Share This Article

Upstream vs midstream vs downstream- what’s the difference between all the three? How are these operations beneficial for oil and gas companies? Know here how intelligent process automation benefits companies by being more efficient.

If you remember, in old times, there used to be a picture of oilmen drilling in the field for oil exploration and equipped with more than their instincts and a chief with hand-scribbled notes. However, those days are now long gone.

Technology has played a crucial role in the modernization of large or small companies, by not only providing automation where there was never before but also improvising the entire process and helping with cost reduction.

Today, the majority of the companies from almost all sectors try to minimize the manual process by opting for software to improve their already existing system. This is ideal for the oil and gas company.

The oil and gas organization has always been an elemental part of the construction and economy. Regardless of which area you belong to, this industry is crucial for a smooth modern society. And this sector is heavily influenced by government regulations, economic factors, and technological advancements.

If you’ve listened to any news on the oil and gas business, then chances are that you might have heard of oil and gas automation. But, what does that mean?

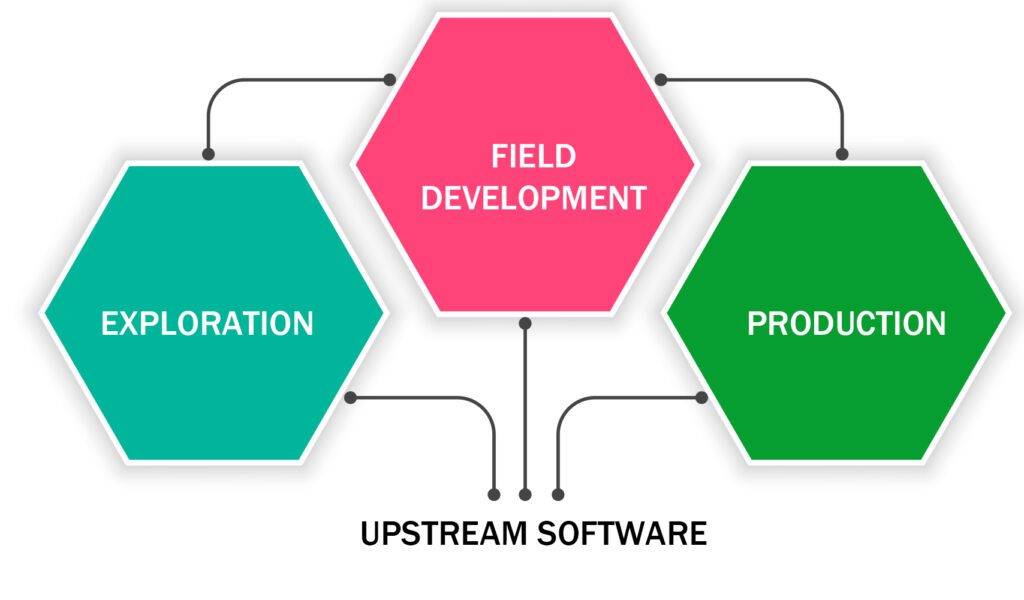

There are actually three related parts to this, upstream software, downstream software, and midstream software.

So, today we are going to discuss intelligent process automation and the difference between upstream vs. midstream vs. downstream. People often get confused and misunderstand the three terms.

Let us clear this out for you.

Evolution Of Oil And Gas Automation

It is very appealing to think of software similar to creating the digital mates of real-world things, for instance, email versus letters and an Excel spreadsheet versus a ledger.

And at a fundamental level, this is very true.

Above all, the oil and gas industry shells out approx. $ 5 billion every year, based on paper records that can be governed more economically by digital document software providers.

With the increasing digital connectivity, the potential to link devices and gather data is also increasing more than ever before. And this concept is termed as Internet of Things (IoT). Thus, the tasks and processes that were done manually are now operated through systems and are linked via software.

For instance- just a few years back, you had to visit your neighborhood to track the route a couple of times and then use your stopwatch or wristwatch to track the total time it would take to run. Now, the smartwatches do the same for you, they automatically track how much distance you have covered.

In view of oil and gas automation, sensors in this sector can at once transmit data for offsite exploration. The oil pump performance can be monitored from a distance rather than depending on regular in-person analysis. Plus, automatic triggers can also be set for emergencies, like shutting down the pump without any human intervention.

Beyond this, oil and gas automation also incorporates intelligent process automation like AI to manage routine tasks and collect information.

In addition to this, the enterprise resource designing software can be utilized for upstream, midstream, and downstream software management.

The oil and gas business revived after many years of deflation. Several oil and gas companies have achieved positive free liquidity, due to various factors. Some of these factors are- higher oil prices, lower interest rates, strong mergers, cash stockpiling, and possession of cross-industry blends.

This global demand put forward the idea of oil and gas companies in a unique way to use digital transformation and achieve sustained benefits.

How does Intelligent Process Automation Impacts The Oil And Gas Industry?

There is no better time to welcome intelligent process automation as the main element of digital transformation and extract maximum advantage from the infrastructure and technology investment.

It’s very difficult for oil and gas industries to have real-time data for increasing productivity. But with Intelligent process automation, one can easily implement manual tasks, automated processes, and hybrid tasks.

Upstream vs Midstream vs Downstream: In Oil & Gas Industry

Oil and gas is a huge industry. The processes in this sector have stretched timelines. In general, the oil and gas production process is segregated into three segments: upstream, midstream, and downstream.

Upstream Software

Upstream signifies the exploration and production section in natural resources. It covers all the tasks related to searching, discovering, recovering, and manufacturing crude oil and natural gas from underground mining.

So, it is about anything related to the research and production of crude oil and natural gas.

With technological advancement, the upstream stage looks for proficient staff who are skilled to work on the latest upstream software to give good results.

The upstream software industry comprises trillions of dollars every year, and around $7 billion are used due to non-productive time, where engineers invest 70 percent of their time in evaluating and manipulating data. Also by taking into consideration the restricted data management capability of companies, the data is limited.

In the oil and gas industry, manual tasks add up to long working hours and a huge workforce without giving good fortune. On top of that, any machine malfunctioning will slow down the process and eventually result in dissent.

Therefore, IoT solutions backed by analytics will permit upstream solutions to keep track of the extraction process from a distanced location in real-time. Through software integration companies can link the latest technologies to change the entire maintenance process by transforming it into a proactive one.

With upstream software, the industry can access all the needed data and facts instantly to get insights. And based on the available information they can organize tasks and minimize the chances of sudden collapse.

The solutions presented in upstream software are-

- Tenure accession

- Accounting

- Land and tenure management software

- Field service management software

- Reservoir management services

- GIS mapping and integration.

Midstream Software

The Midstream segment connects the upstream and downstream segments. In the midstream segment, the crude oil and natural gasses are processed, stored, and then transported and sometimes advertised to wholesale customers.

Here the main task is to focus on how the resources can be deployed and processed effectively. Sometimes it is also referred to as pipelines and infrastructures required to transport the resources at long distances.

Our software development services for the midstream segment can manage the task of processing, transportation, storing, and marketing oil and natural gas.

Since the company has to transport oils from one location to another through pipelines, there is always a constant threat from thieves who drill the pipes to steel oils.

However, with Midstream software solutions you can experience a significant advancement in the pipeline’s safety.

The intelligent process automation is designed to evaluate the pressure of oil in the pipelines. So as long as there is no leak, the pressure will be constant, by this, you can keep track of the transportation.

The solutions presented in Midstream software are-

- Crude oil management

- Pipeline performance tracking system

- Oil and gas pipeline management system

- LNG management

- Oil and natural gas transportation management system.

Downstream Software

Downstream is the final stage in the oil and gas industry. This comprises everything that is done to turn crude oil and natural gas into various finish products that we need on a daily basis.

Some of the common by-products are gasoline, diesel, kerosene, jet fuels, heating oils, and asphalt. Plus, the long-chain hydrocarbons present in both crude oil and natural gas are further utilized to manufacture less obvious products such as synthetic rubbers, preservatives, containers, and plastics for infinite products. Paints, dyes, and fibers manufacturing have some connections to oil and natural gasses.

The downstream software helps in monitoring costs and boosts performance. Plus with the downstream software, you can keep eye on the incidents like spills, emissions, and other accidents.

Solutions presented in downstream software are-

- Cost monitoring

- High-performance terminal management system (TMS)

- Replenishment and distribution management (RDM)

- Identifying potential refinery threats.

Upstream vs Midstream vs Downstream: How They Are Benefited By Software Development

For any company that operates on technology, software development also becomes important for conducting business. This fit is perfect for the oil and gas industry as well.

Here’s how the upstream, midstream, and downstream are benefited from the software development:

Data Security

Data security is a crucial issue in all industries. And malicious attacks in the post-pandemic era have surged in both state-run and private sectors.

This is the reason businesses seek a safe solution to protect their sensitive data in various ways.

Personal Safety

In the oil and gas industry, one thing is common, the focus on people’s safety, especially when they are working with flammable materials. With oil and gas automation, the industries can overcome the issue of the safety of their workers.

Today, the most common use of technology is in the personal safety area. With intelligent process automation and software development, we can design creative risk detection mechanisms like real-time sensors and biometric scanners.

Efficiency

In the oil and gas industry that moves so much one currency, can always be improvised to become more efficient in execution, thus saving time and material. The software applications in these sectors can collect information and store it in their repositories.

Drilling Assistance

Drilling is the most important task in the oil and gas industry, and acquiring improper techniques can lead to financial disasters. However, with the integration of artificial intelligence(AI) and sensors, one can improve the drilling process.

Chemical Analysis Processes

The oil and gas industry works with substances extracted from the environment, but these materials are not ready to be transported or marketed. There are many unwanted materials mixed with the main one, and so they must be removed.

These processes are carried out via chemical analysis processes that involve various separate tasks like extraction, laboratory tests, obtaining certain parameters to achieve the desired objectives.

Summary

There is always fierce competition, and in the oil and gas industry where there are outside players like renewable energy companies, the competition is increasing daily.

So, in the comparison of Upstream vs Midstream vs Downstream- Upstream is about extraction and production, Midstream is about safely transporting materials, and downstream involves transforming these resources into finished products.

These three segments together sustain the constant flow of fuels and materials that makes the life of employees better and safer. Accessing and analyzing capital from upstream, midstream, and downstream segments and linking oilfield data into useful information-anywhere-is crucial to remain ambitious as this sector keeps evolving.

Contact us for more information. We will get back to you with all the relevant information.